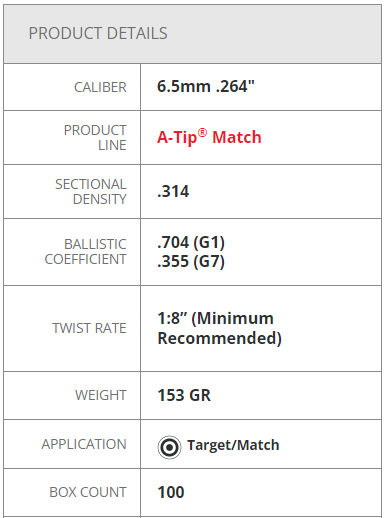

Years of research and testing by the Hornady® Ballistic Development Group, combined with advanced manufacturing processes and quality control measures have led to the creation of the ultimate low drag, high performance match bullet.

Use of a new A-Tip® seating stem is required for optimal bullet seating.

Product Features

TIP DESIGN

- Aluminum tip is precision machined and longer than polymer tips which moves the center of gravity and enhances inflight stability.

- Aeroballistically advanced tip design results in tighter groups and reduced drag variability.

- Perfect blend of ogive, tip length, bearing surface and optimized boattail by caliber.

PERFORMANCE

- Doppler radar verified low drag coefficient (high BC) bullets are forgiving of twist rate, seating depth and muzzle velocity.

- Refined design of the AMP® bullet jacket offers industry leading uniformity and concentricity.

MANUFACTURING

- Right off the press – sequentially packaged, one clone after another for the ultimate in consistent performance.

- Minimal handling throughout the manufacturing process ensures consistency from bullet to bullet.

- Packaged with a polishing bag to prepare bullets for loading (bullets aren’t bulk washed after manufacture).

- Diameter:

- .264 / 6.5mm